Tissue Folding Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Tissue Folding Machine Solution

With the continuous improvement of the level of my country's catering industry, the demand for napkins is increasing. Therefore, the market for equipment for making napkin machines has also increased.

The paper towel folding machine system occupies an extremely important position in the current production of the paper towel industry. Compared with the traditional semi-automatic paper folding machine, the more automated and efficient paper folding system occupies a great advantage in this industry and has a broader application prospect.

Features and Benefits

Industry introduction

Paper towels are common daily necessities in people's lives, and consumers have a huge demand for paper towels. With the increasing consumption of paper towels, there is an urgent need for an intelligent, efficient, stable, and reliable automatic paper towel folding machine system to meet the current market's growing output demand.

System solution realization

System solution realization

The control system adopts the high-performance V5 motion controller of VEICHI, and through the external encoder pulse output feedback of the main shaft, the dragging shaft and the separating shaft follow the electronic cam motion and alternately coupled at the same time. The actions of the material rack, conveyor belt, fan, and cylinder are coordinated with each other, and the HMI man-machine interface is freely adjusted, which realizes the system's high efficiency and maneuverability.

Advantages

1. A full set of technology, flexible and stable

The core products of the entire system solution are all high-performance automation products from VEICHI to ensure that the entire control system such as motion controllers, servos, inverters, and touch screens can achieve higher stability and compatibility. At the same time, it can cooperate with customers to provide more flexible solutions and after-sales service.

2. Replace the complex with simple, accurate and reliable

Both the paper separating axis and the dragging axis of the system follow the feedback pulse of the spindle encoder to make the electronic cam track movement. Compared with the traditional speed ratio and positioning method, its movement method is simpler, more accurate, and more stable.

3. Strong operation control, high precision

The action trigger of the fork paper servo adopts a high-speed comparison setting trigger, and the encoder Z signal is interrupted, which ensures that the Y output of the fork cylinder is not affected by the program scan cycle. Set different angles to insert, the response error can be controlled within 1ms.

4. High frequency response, extremely fast communication

The frequency conversion frequency of multiple material racks is given by the spindle PUL pulse input, and the material rack speed ratio is set in real-time following the spindle through 485 communication. The adjustment is convenient, the speed setting precision is high, and the synchronization is strong.

5. Upgrade again safely

The system alarm safety logic is complete, involving controllers, inverters, servos, cylinders, fans, etc., in case of any misoperation, to ensure that the system is protected in time.

Relying on strong R&D strength and advanced core technology, it has always been the original intention of VEICHI to create intelligent system solutions tailored to customers and to promote the continuous upgrading and optimization of the manufacturing ecosystem.

Program highlights

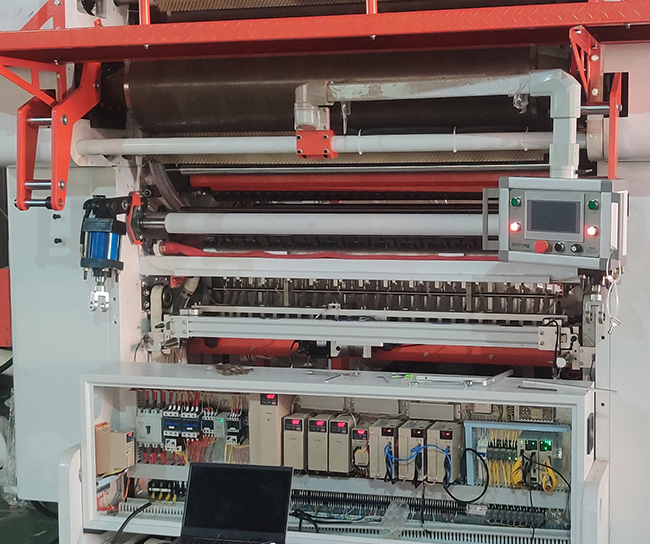

1. The system adopts VEICHI V5-MC104 motion controller, dual CPU hardware architecture, and the underlying processing speed is faster.

2. Man-machine interface centralized control, stable performance, easy to operate and maintain.

3. Both the paper separating axis and the dragging axis of the system follow the feedback pulse of the spindle encoder to make the electronic cam track movement. Compared with the traditional speed ratio and positioning method, the movement method is simpler, the precision is higher, and the stability is stronger.

4. The connection between V5 controller and servo adopts a high-speed differential signal, which has high stability and is not easy to interfere with. The maximum pulse speed of the differential pulse port is 3MHz, which can achieve extremely high control accuracy.

Process principle

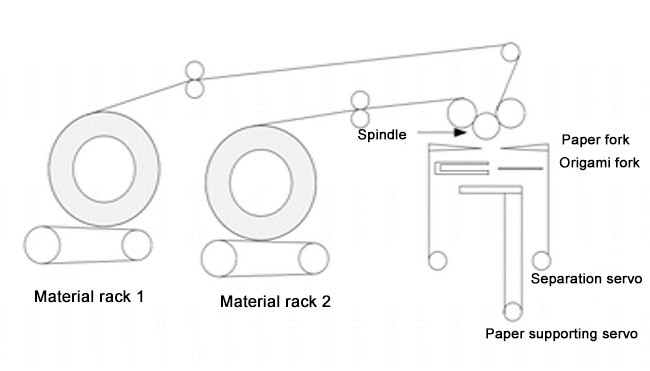

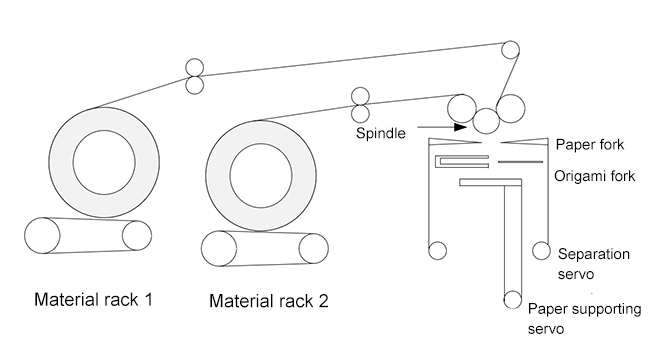

The structure of the high-speed paper towel folding machine is mainly composed of the following parts:

Spindle paper folding mechanism: Driven by the frequency converter, it cuts and folds the paper towels from the conveying mechanism of the two racks.

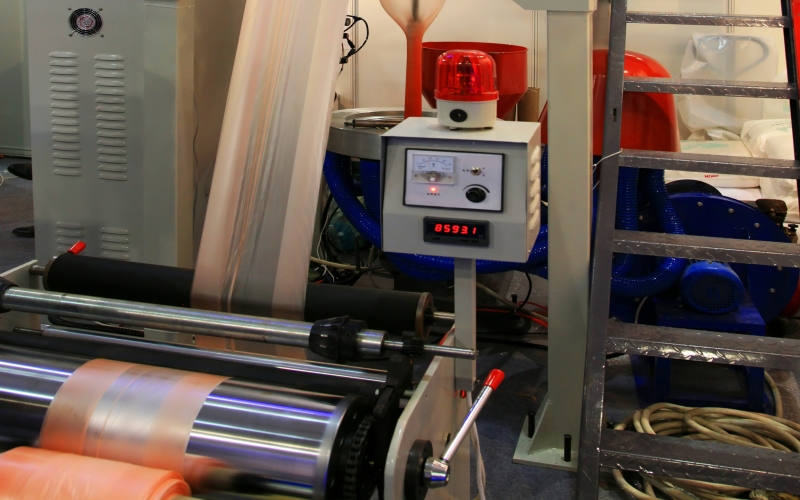

Material rack conveying mechanism: Driven by two inverters, the frequency is given by the spindle pulse output, and the relative spindle speed ratio of the two inverters can be changed in real-time through the 485 writing method to adapt to the feeding and conveying of the origami raw materials Appropriate speed.

Conveyor belt mechanism: It is mainly used to transfer the folded paper to the next processing link for subsequent processing.

Separation shaft mechanism: Driven by a servo driver, it follows the main shaft to do the first position cam position movement part.

Paper drag shaft mechanism: Driven by a servo driver, it completes the coupling operation part of the electronic cam of the spindle and the slave axis at the second position.

Cylinder action mechanism: including fork cylinder, horizontal push cylinder, paper folding cylinder, and paper push cylinder, etc.

Technical index

Processing smaller paper (50 sheets/pack) can reach 70M/min.

When the number of sheets is more than 100 sheets, the efficiency can be increased to more than 85M/min.

Function upgrade, advanced technology

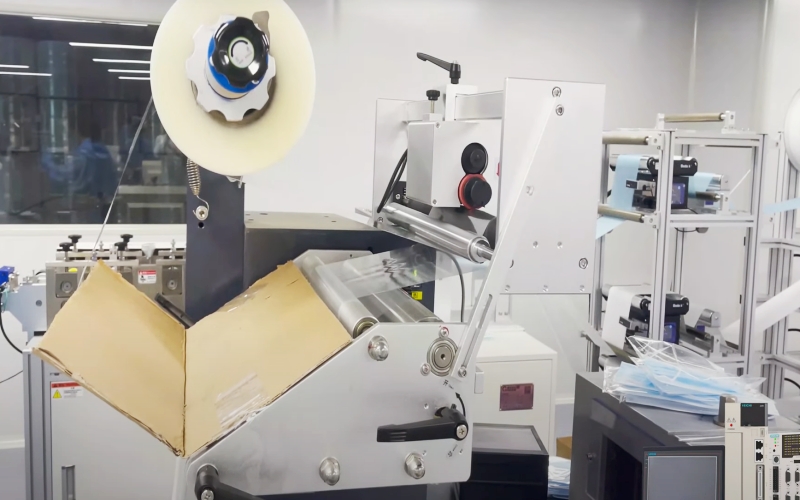

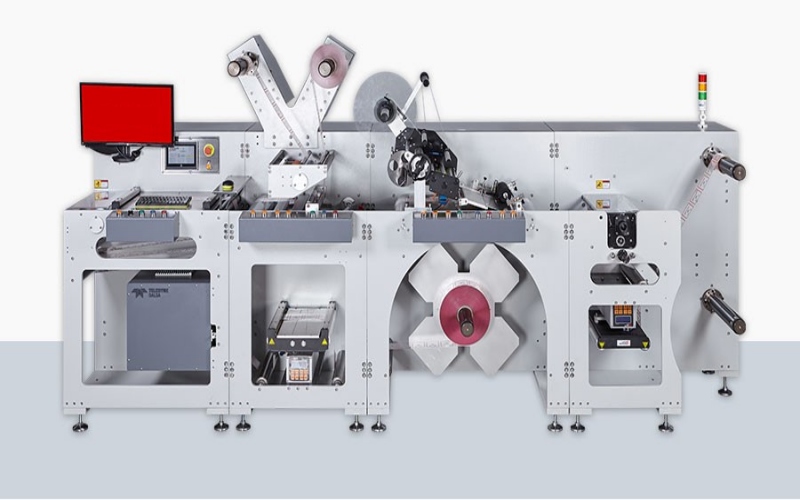

Field application examples

As a well-known intelligent manufacturing system solution provider in the industry, VEICHI combines user feedback and actual application scenarios to launch a fully automated tissue folding machine system solution with higher automation, greater stability, and faster production efficiency. The maximum linear speed of equipment operation can reach above 100M/min.

Equipment structure

Equipment structure

1. Spindle paper folding mechanism: Driven by the VEICHI AC310 series high-performance inverter, it cuts and folds the paper towels from the two racks, and its speed is required to remain stable. The main shaft is equipped with an external encoder, which serves as the pulse feedback of the two electronic cams of the paper drag shaft and the paper separation shaft, and also serves as the pulse feedback of the insertion angle of the two fork paper servos.

2. Material rack transmission mechanism: Driven by two VEICHI AC310 series inverters, the frequency setting method is the PUL pulse output setting. Ensure that the linear speed of multiple racks unwinding Frequency converters is consistent with the spindle cutting and folding linear speed.

3. Conveyor belt mechanism: It mainly transfers the folded paper towels to the next processing link (big round) for cutting and processing. The conveyor belt is driven by the VEICHI AC10 series of simple inverters.

4. Separation shaft mechanism: Driven by VEICHI SD700 series high-performance Servo System, the servo follows the main shaft to make cam curve movement.

5. Paper drag shaft mechanism: Driven by VEICHI SD700 series high-performance servo system, the servo follows the paper separating shaft mechanism to do superimposed cam motion.

Application

Three-side sealing bag making machine

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message