• SD700 PA, SD700 SA, SD700 CA SD700 EA, SD700 MA, SD700 LA, SD700 FA;

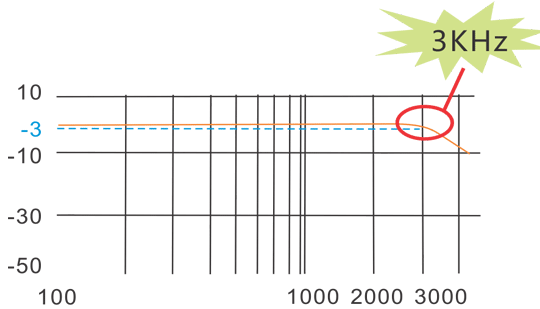

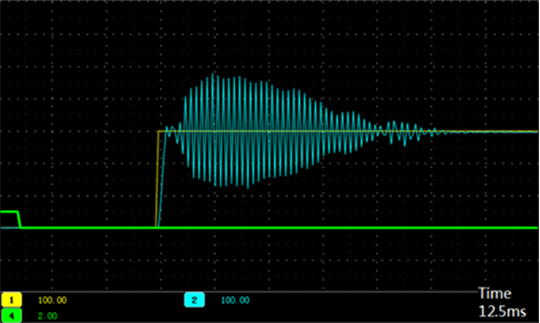

• 3KHz speed loop response bandwidth;

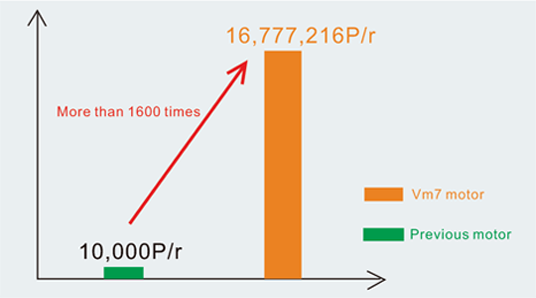

• 17bit, 23bit, 24bit encoder;

• Modbus, CANopen, EtherCAT, Profinet, MechatroLink II, MechatroLink III;

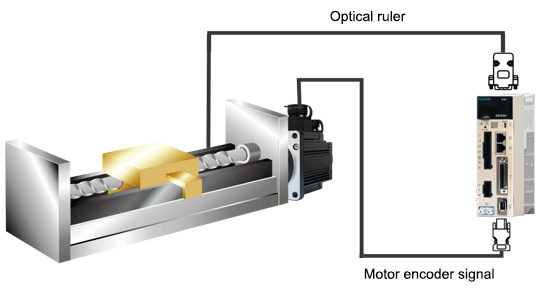

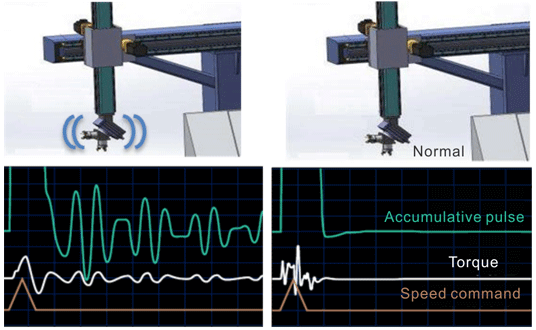

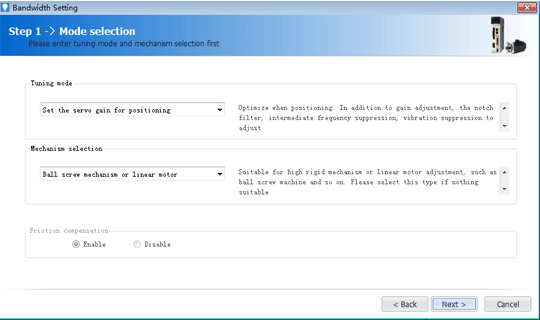

• ECAM; Full closed loop model; Low frequency vibration suppression;

• Robust control; Auto set notch filter; AI setting;

• Speed observer; STO (optional);

• Voltage: 1 Phase 220V, 3 Phase 220V - 400V;

• Power: 0.1kW - 55kW, customized up to 250kW;

• Support EtherCAT, RS-485, CANopen;

• 3KHz speed loop response bandwidth;;

• Low frequency, mid frequency, high frequency damping;

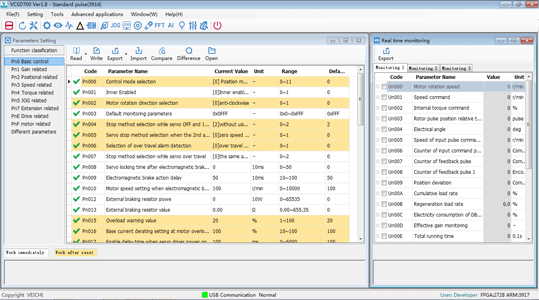

• Powerful PC software;

• Simple and practical selection software;

• Easy to debug;

• Easy to install;

• Book design, compact size;

• Power: 100W - 1kW;

• Protection level IP67;

• Higher motor accuracy;

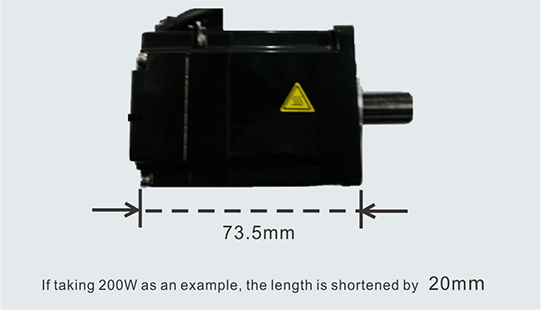

• Shorter motor length;

• Lower motor temperature rise;

• Comprehensive motor power range;

• Simple wire replacement;

• Integral design, more beautiful;

• Higher energy efficiency

• Power: 100W - 7.5kW;

• High speed up to 6000rpm;

• 3-4 times overload capacity;

• Reduce volume by more than 20%;

• Protection level IP67;

• 17bit, 23bit, 24bit encoder;

• Low inertia, Medium inetia, High inertia;

• Flange 40mm~260mm, Customized the higher flange;

• 1500rpm, 2000rpm, 2500rpm, 3000rpm;

• 0.1kW~55kW, customized up to 250kW;

* Experienced R&D team

* One stop solution

* Factory sold directly

* 18 months long warranty

* Full series CE certification and ISO 9001

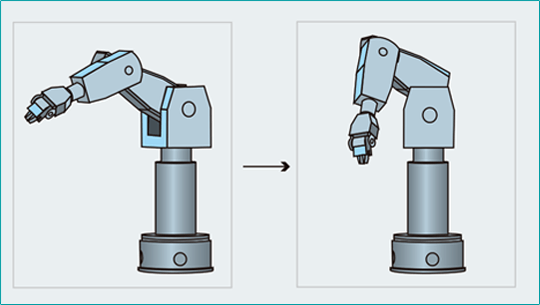

A: A servomotor is a rotary actuator or linear actuator that allows for precise control of angular or linear position, velocity and acceleration. It consists of a suitable motor coupled to a sensor for position feedback.Look More

A: Please directly provide voltage, power, torque, inertia, running speed, encoder type, braking type, etc and usage occasion or our models.

A: All of our products adopt the full inspection and full test mode to ensure that each manufactured product is qualified.

A: Generally it is 5-10 working days if the goods are in stock. or it is 15-20 working days if the goods are not in stock, it is according to quantity.