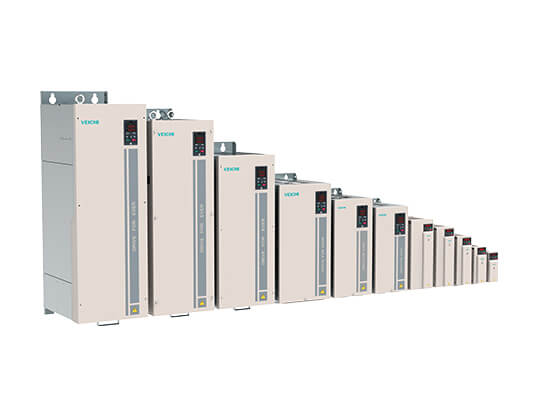

Low Voltage Drives

As the leading VFD manufacturer, VEICHI Electric provides a full range of products such as low voltage inverter at wholesale price. If you need high performance AC low voltage inverters for your system, then you've already come to the right place as VEICHI provides a wide range of choices that you can rely on. According to our customer requirements, VEICHI has developed AC310, AC10 and more lower voltage frequency inverter models which are best selling products with great quality, outstanding performance, high stability and accuracy.

Please click me to view the video about VEICHI VFD.

-

AC310 Series Variable Frequency Drive - AC Drive

AC310 series AC Drive VFD of VEICHI is a product that continues to be developed on new high-performance vector technology platform.

-

AC10 Series Variable Frequency Drive - AC Drive

AC10 series frequency drive is a product developed on the latest technology platform of VEICHI. AC10 products are based on the market demand for miniaturization, high reliability and high cost performance.

-

AC01 Series Network Type AC Drive

AC01 network type acdrive is designed with a wire groove on the terminal side. The control wires and the main circuit wires can be directly bundled and guided to the junction slot. Ensure beautiful wiring when using in cabinets or stand-alone.

-

AC330 Special Frequency Inverter for Synchronous Reluctance Motor

The AC330 series inverter is further optimized on the VEICHI AC310 product platform, integrating the drive control concept of the synchronous reluctance motor, and developing a new vector control algorithm.

-

AC200 High Performance Vector Control AC Drive

VEICHI AC200 series AC drive is developed with advanced real-time high performance vector control algorithm.

-

AC70 Series Variable Frequency Drive - AC Drive

VEICHI AC70 is a powerful sensorless vector power control ac drive for induction motor. The sensorless vector control drive is of high reliability and powerful functions.

More About Low Voltage Drives

Variable Frequency Drive (VFD) is also be called AC drive, adjustable frequency drive, variable speed drive (VSD), variable frequency inverter (VFI). Whatever the name, VFD is a type of motor controller that drives and controls an electric motor. The VFD controls the motor speed and torque to meet the application’s requirements by varying the frequency and voltage supply.

Even though the drive controls the frequency and voltage of power supplied to the motor, we often refer to this as speed control, since the result is an adjustment of motor speed.

Why adjust this motor speed?

For example:

- Save energy and improve system efficiency;

- Convert power in hybridization applications;

- Match the speed of the drive to the process requirements;

- Match the torque or power of a drive to the process requirements;

- Improve the working environment;

- Lower noise levels, for example from fans and pumps;

- Reduce mechanical stress on machines to extend their lifetime;

- Shave peak consumption to avoid peak-demand prices and reduce the motor size required;

What's the difference between a VFD, an AC drive, and a variable speed drive?

None. All these names refer to the same kind of devices, also known AC variable speed drives, AC variable frequency drives, VFD inverters or variable voltage variable frequency drives.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message