- Home > Product > Industry-specific Drive > Compressor > AP100 Series PMSM Air Compressor Purpose VFD

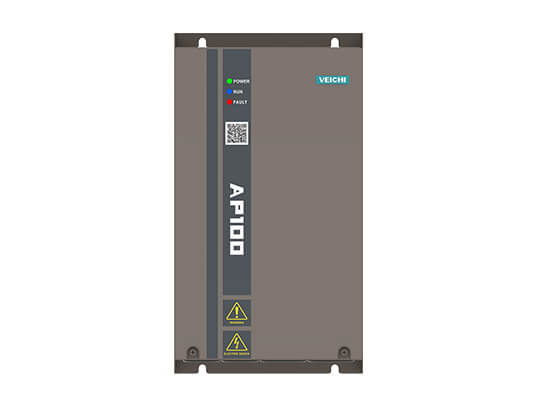

AP100 Series PMSM Air Compressor Purpose VFD

- Perfectly drive synchronous and asynchronous multiple screw compressors

- Pre-determined motor demagnetization mechanism to prevent irreversible motor demagnetization

- Industry-leading fuzzy PI algorithm with fast regulation, fast response and no overshoot

- Intelligent IOT system & real-time monitoring of air compressor field application remotely

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

AP100 Series PMSM Air Compressor Purpose VFD Overview

AP100 air compressor implements remote monitoring of the air compressor on-site application status. GPRS wireless transmission technology, intelligent fault detection, SMS notification. During operation, the magnetic field of the motor can be directly monitored, and early warning can be made to reduce the probability of loss of magnetization of the motor.

1. Three-in-one design to meet the various needs of customers.

2. High protection level, strong environmental adaptability.

3. Perfectly drive synchronous and asynchronous screw compressors of various types.

4. Intelligent IOT, real-time remote monitoring of air compressor field application conditions.

5. The intelligent energy-saving vector control algorithm, small current, large output, and energy saving.

6. Double predictive motor demagnetization mechanism to prevent irreversible demagnetization of the motor.

7. Fuzzy PI algorithm, fast voltage regulation, fast response, no overshoot.

8. The fuzzy PI algorithm, fast voltage regulation, fast response, no overshoot.

New dark gray shape, details show quality

1. The dark gray metal shell with black stripes is simple and elegant.

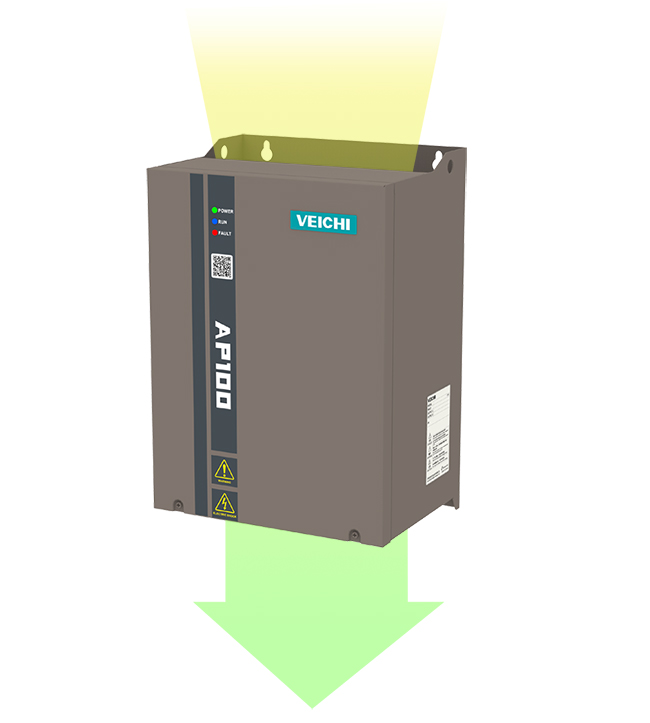

2. The humanized air duct design is convenient for disassembly, cleaning, and maintenance, and the heat dissipation effect is enhanced.

Highly integrated, multiple functions in one

1. Three-in-one design of the main engine, fan, and oil temperature fan.

2. VEICHI AP100 integrates air compressor control technology, which is convenient for wiring.

3. Using TI high-performance DSP chip, more reliable and less noise.

High protection level, no oil pollution

1. The high degree of protection, anti-oil, metal powder, and high temperature caused by cotton wool.

2. It can be applied to harsh sites such as machine tools, textiles, and stone.

The energy-saving vector control algorithm

1. Under the air supply pressure, the operating current is small, the output is large, and the energy-saving is excellent.

2. In response to current high-frequency operation requirements, VEICHI AP100 has a 600Hz vector control algorithm.

3. The fuzzy PI algorithm, no overshoot, fast voltage regulation.

Intelligent IOT, all in the cloud

1. Real-time remote monitoring of the on-site application of the air compressor.

2. GPRS wireless transmission technology, intelligent fault detection, SMS notification.

3. Support functions such as remote switch on/off, appointment lock, and maintenance information query.

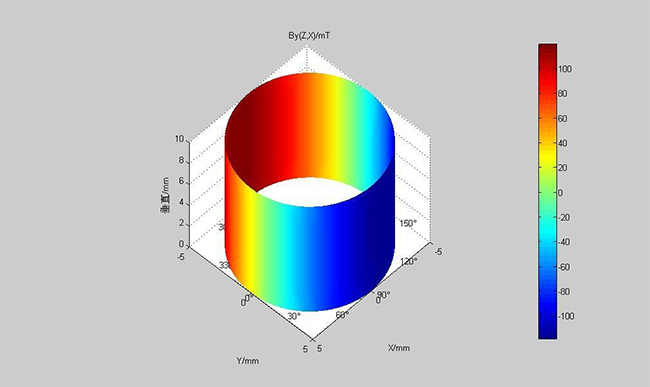

Detect the motor magnetic field to avoid demagnetization

1. VEICHI AP100 can directly detect the motor magnetic field during operation.

2. Early warning in case of possible loss of magnetism, reducing the probability of motor loss of magnetism.

3. It has a motor temperature detection function to prevent PMSM from being irreversibly demagnetized due to overheating.

AP100 Series PMSM Air Compressor Purpose VFD Video

Industrial Applications for AP100 Series PMSM Air Compressor Purpose VFD

Applications:Pneumatic and pneumatic control, air drive and participation in chemical reactions, etc.

Specifications

| Power range | 7,500 W-90,000 W |

|---|

| Voltage and frequency | Three-phase 380V 50/60Hz |

|---|---|

| Allowable fluctuation range | Voltage ±15%; Frequency: ±5%; Distortion rate meets IEC61800-2 requirements |

| Closing impulse current | Less than rated current |

| Inverter efficiency | ≥96% |

| The output voltage | Output under rated conditions: 3-phase, 0~input voltage, error less than 5% |

|---|---|

| Output frequency range | 0~400Hz |

| Output frequency accuracy | ±0.5% of maximum frequency value |

| Overload capacity | 150% rated current for 60s, 180% rated current for 10s, 200% rated current for 2s |

| Motor control mode | No PG vector control, V/F control |

|---|---|

| Modulation | Optimize space vector PWM modulation |

| Carrier frequency | 0.6~15.0kHz, random carrier modulation |

| Speed control range | Vector control without PG, rated load 1:100 |

| Steady-state speed accuracy | Vector control without PG: ≤1% rated synchronous speed |

| Frequency accuracy | Digital setting: maximum frequency×±0.01%; analog setting: maximum frequency×±0.2% |

| Frequency resolution | Digital setting: 0.01Hz; Analog setting: maximum frequency×0.05% |

| Torque boost | Automatic torque increase 0.0%~100.0%; Manual torque increase 0.0%~25.0% |

| Rated output voltage | Using the power supply voltage compensation function, the rated motor voltage is 100%, which can be set in the range of 50 to 100% (the output cannot exceed the input voltage) |

| Automatic voltage adjustment | When the grid voltage fluctuates, it can automatically keep the output voltage constant V/F |

| Automatic energy saving operation | According to the load condition, the output voltage is automatically optimized to realize energy-saving operation |

| Automatic current limit | Automatically limit the current during operation to prevent frequent over-current fault trips |

| Instantaneous power failure processing | In case of instantaneous power failure, uninterrupted operation is realized through bus voltage control |

| Input command signal | Motor temperature detection (compatible with PTC, KTY84), oil temperature detection PT100, pressure detection (4-20mA) |

| External output signal | 3 relay outputs, including loading valve, start-stop switch of oil pump, start-stop of main engine cooling fan |

| Protective function | Host overcurrent, overload protection, fan overload protection, thermal relay protection, overheat protection; protection against motor demagnetization, etc. |

|---|

| Installation site | Indoor, the altitude is lower than 1000m, no corrosive gas and direct sunlight |

|---|---|

| Temperature and humidity | From -10℃ to +40℃ 20%~95%RH(No condensation) |

| vibration | Less than 0.5g below 20Hz |

| Storage temperature | From -25℃ to +60℃ |

| Installation method | Wall-mounted, vertical cabinet |

| Protection level | IP20 |

| Cooling method | Forced air cooling |

Downloads

| File Name | Type | Language | File Type | Update | Download |

|---|---|---|---|---|---|

| Introduction of Internet of Things | Catalog | English | 2018-02-04 | 2.4MB | |

| System Control Solution of Air Compressor Catalog V1.0 | Catalog | English | 2022-03-29 | 16.6MB | |

| AP100 Series Air Compressor User Manual V1.1 | Manual | English | 2020-04-16 | 3.10MB |

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message