- Home

- Industry News

- SD700 CANopen bus application case of VEICHI

With the development of modern industrial technology, some automation equipments are becoming more and more complex, and the performance requirements are getting higher and higher. The traditional pulse-type servo drives have gradually failed to meet the customer's requirements for servo performance. The bus type servo driver transmits the control signal by means of communication, so it perfectly avoids the drawbacks of the traditional pulse type servo driver (loss of pulse, complicated wiring, and excessive use of PLC resources). In the future, the bus type servo driver is inevitable. It is a development trend in the servo industry. The R&D team of VEICHI, which has been committed to research and development and innovation, has introduced CANopen, EtherCAT, MII, MIII and other bus-type servo drives. These bus protocols are designed in strict accordance with international standards, whether you are doing a replacement or doing development, it is perfectly compatible.

The R&D team of VEICHI that has been committed to research and development has introduced CANopen, EtherCAT, MII and other bus-type servo drives. The bus protocols inside the servo drives are designed in strict accordance with international standards and have been repeatedly tested and verified. Whether you are doing it as an alternative or developing it, it is perfectly compatible with other devices.

The SD700 CANopen bus model is the first generation of bus-type servo driver introduced by VEICHI. Since the introduction of this bus model, it has obtained a large number of successful applications on the client side and has won unanimous praise in the industry. The following are the most representative success stories selected across the country.

The application of VEICHI SD700 bus servo drive on the terminal machine

| Equipment use: | Cutting, stripping, smearing, immersing tin, etc. |

| Production speed: | 6500 roots / hour |

| Bus type: | CANopen |

| Number of axes: | 7 axis |

| Communication baud rate: | 1Mbps |

| Application area: | South China |

The terminal machine control system is a set of systems developed by the servo application development team of VEICHI for the terminal machine industry. At present, the actual application has been obtained on the client side. The terminal machine has high requirements for the comprehensive performance of the servo drive. In order to improve the production speed, the driver that controls the displacement of the terminal must require fast positioning, otherwise the production efficiency will be reduced, and the positioning accuracy is also high. If the positioning deviation is too large, the yield will be lowered, and the servo of the skinning knife will be controlled. The requirements will be higher, not only the accuracy and speed of positioning, but also the overshoot should be prevented under the premise of accurate positioning, because once overshoot occurs, it is possible to strain the copper wire of the core while peeling, resulting in an increase in the defect rate. Even if the terminal machine has high requirements for the driver, the bus type servo driver of VEICHI can handle it perfectly.

1. Equipment running video

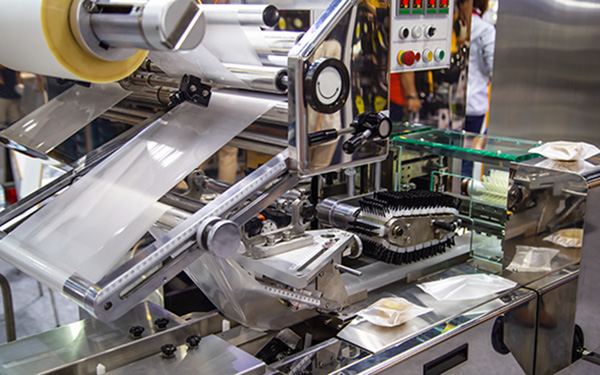

2. Equipment picture

Equipment picture

3. Product photo

Product photo

Cold bending machine

| Equipment use: | Cold bending forming of metal materials |

| Bus type: | CANopen |

| Number of axes: | 104 axis |

| Communication baud rate: | 250Kbps |

| Application area: | North China |

This equipment is a system developed by customers using the SD700 bus controller of VEICHI. Due to the excessive number of system axes, in order to ensure the reliability of communication, the communication baud rate is reduced to 250Kbps, and the equipment has lower requirements for axis synchronization. The 250Kbps communication Portland is fully capable of meeting customer requirements.

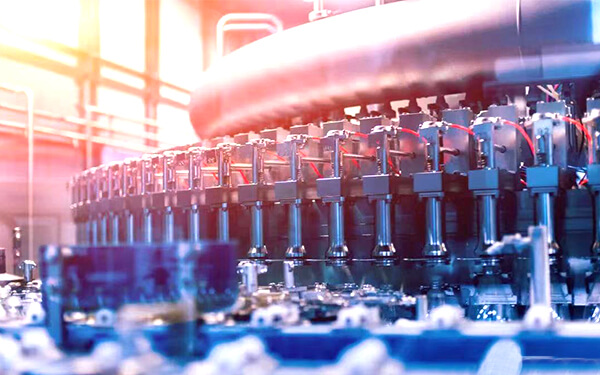

1. Equipment picture

Equipment picture

Thin knife separator

| Equipment use: | Cutting corrugated paper, creases, etc. |

| Bus type: | CANopen |

| Number of axes: | 13 axis |

| Communication baud rate: | 1Mbps |

| Application area: | South China |

The thin knife paper separator is a system solution developed by servo application development team of VEICHI for customers. The thirteen servos operate perfectly at a communication baud rate of 1Mbps, and there has been no problem since it was put into production.

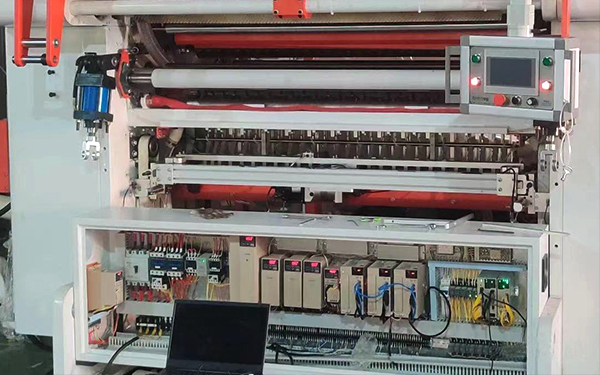

1. Live photo

Live photo

Conclusion:

The bus-type servo drives of VEICHI are now perfectly compatible with most of the mainstream controllers on the market. Customers can use bus-type servo drives of VEICHI to develop systems without worrying about compatibility issues. The V5 motion controller of VEICHI also supports the control of the AC Servo System via the bus mode.

Of course, VEICHI also has a professional system application development team. If customers need it, we will provide you with a complete set of system solutions according to your needs, including early development and design, and after-sales service.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message